Chery Surpasses Xiaomi With New 2,400 MPa Hot-Stamped Steel — A World Record

A breakthrough in next-generation automotive materials

Chery, working together with the metals producer HBIS Group, announced a major leap forward in automotive materials: the development of a hot-stamped steel boasting an ultra-high strength of 2,400 megapascals.

Reaching the 2,400 MPa threshold marks a meaningful step for China’s materials science. Hot-stamped steel sheets are essential in modern vehicle construction, forming the backbone of key passive-safety structures — the A/B pillars, door intrusion beams, door rings, and floor crossmembers. These components play a crucial role in protecting occupants and maintaining body integrity during a crash.

Until now, automakers typically relied on hot-stamped steel in the 1,300–1,800 MPa range. The long-standing challenge has been pushing strength even higher without compromising toughness, consistency, or formability — a difficult balance to achieve. The joint work between Chery and HBIS appears to have cracked the problem, producing a material that raises strength while maintaining excellent forming performance and process stability.

The new 2,400 MPa hot-stamped steel brings three major advantages:

- Enhanced safety: The higher strength significantly improves impact resistance in critical structural safety parts.

- Weight-reduction potential: Stronger steel allows engineers to use thinner sections, creating new opportunities to cut vehicle weight, which in turn can improve fuel efficiency, reduce emissions, and boost performance.

- Balanced material properties: The steel combines extreme strength with solid toughness and formability, tackling the industry-wide issue of brittle high-strength materials that are difficult to work with — all while remaining viable for mass production.

Chery says the material has already undergone extensive testing, including trial stamping of real components, vehicle installation, and multiple rounds of validation — door intrusion beams among them. These tests confirmed stable mechanical properties, a predictable forming window, and precise dimensional accuracy, indicating that the material is ready for high-strength safety applications in production. Looking ahead, Chery and HBIS plan to expand its use to other major structural pieces such as door rings, longitudinal members, and crossmembers.

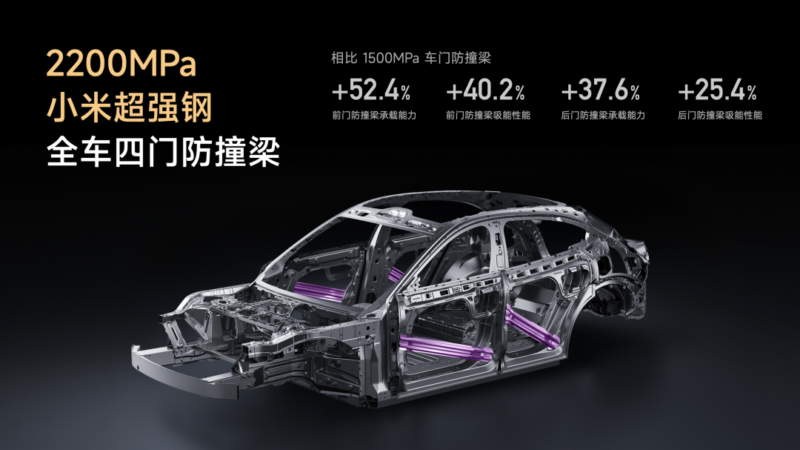

Until now, the global record for ultra-high-strength steel used in a production vehicle belonged to Xiaomi’s YU7, rated at 2,200 MPa.

You may also be interested in the news:

Ford and Xiaomi Deny Rumors of Joint EV Production in the U.S.

Speculation about a potential partnership between America’s Ford and China’s Xiaomi intensified after a report published by the Financial Times.

Why Bird Droppings Are Dangerous and How to Remove Them from Your Car Without a Car Wash

Bird droppings are more than just annoying—if left on your car, they can seriously damage the paint.

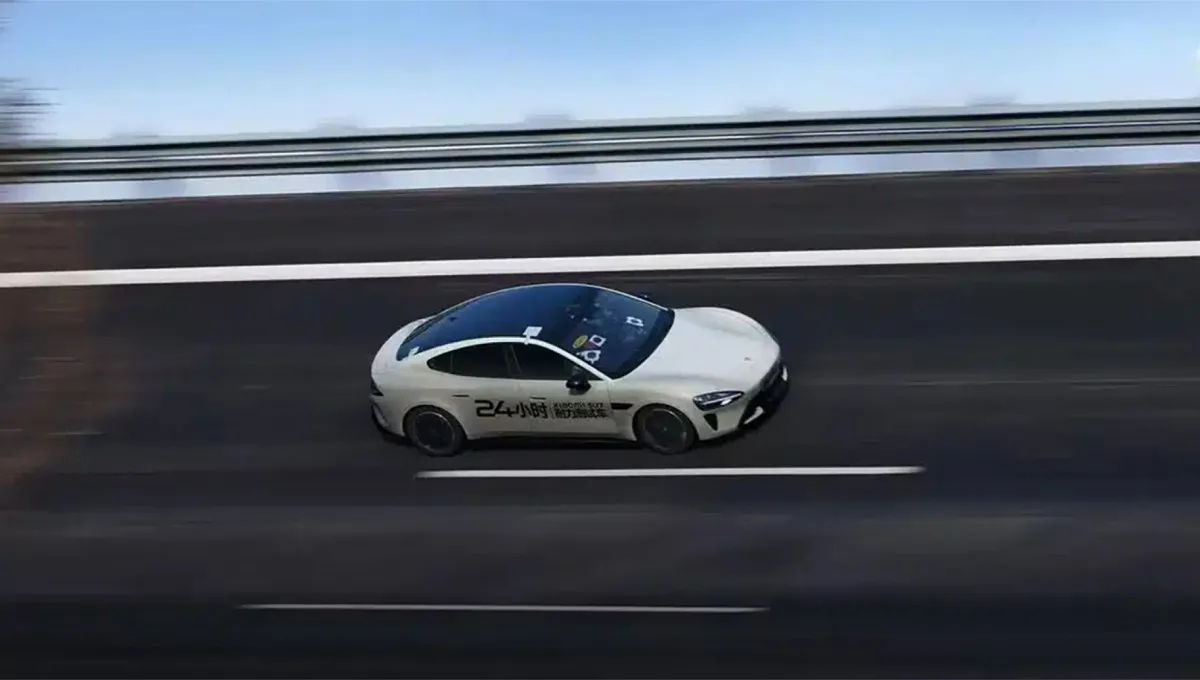

Xiaomi SU7 Covers 2,649 Miles in 24 Hours — Test Details Revealed

Xiaomi has called the results of testing its updated SU7 electric sedan record-breaking.

The End of Winter Woes for EVs: Batteries Announced That Work at −22°F

This would be one of the first uses of solid-state batteries in passenger vehicles.

How to Fix a Deep Scratch on Your Car at Home – Yes, It’s Possible

Tiny scratches can usually be removed with a thorough polish, but what about deep scratches? Here’s how to tackle them yourself.