Many American drivers notice round holes in the asphalt — most don’t know why they’re there

People have been speculating for years about what these holes really are.

Every driver has probably noticed those strange, circular holes in the asphalt at least once. Over time, countless theories—some wild, some downright absurd—have sprung up about what causes them. Some of the guesses are so out there that it’s hard not to chuckle. It’s time to set the record straight and explain exactly what these odd little pits really are.

These holes are actually the result of removing cylindrical cores, commonly called “cores,” from the pavement. Typically, several cores are taken from different spots. Over time, myths and misunderstandings about why this is done have built up, but the reality is much simpler than the rumors suggest.

Some people think these cores are cut out to allow the asphalt to expand and contract with heat. Others assume they’re part of a drainage system. A few have even come up with full-blown conspiracy theories. In truth, the process is straightforward and entirely practical.

Cores are usually taken within a few days of paving. Specialized equipment—a core drill or a saw designed for hard materials—is used to cut them out. The samples are then sealed in protective containers and sent to a laboratory, where they are tested to determine the quality of the pavement.

What is a Core in Road Construction?

A core is a cylindrical sample of asphalt or concrete removed from the pavement for laboratory testing. These samples help engineers measure:

- Material density and porosity

- Bitumen content (for asphalt)

- Compressive strength (for concrete)

- Wear and durability of the surface

How It’s Done in the U.S.:

Special core drills are used—usually electric or gas-powered—with diamond-tipped bits.

- Cores are typically 4–6 inches in diameter and about 6 inches deep.

- Once extracted, the samples are packed and sent to a lab for analysis.

When and Why Cores Are Taken:

- During the construction of new roads, to check mix quality and compaction

- When repairing or inspecting existing roads, to assess whether reinforcement or replacement is needed

- Sometimes as part of contractor compliance testing

It’s a routine practice and perfectly safe for the pavement. After the cores are removed, the holes are filled with fresh material and compacted to restore the road surface.

You may also be interested in the news:

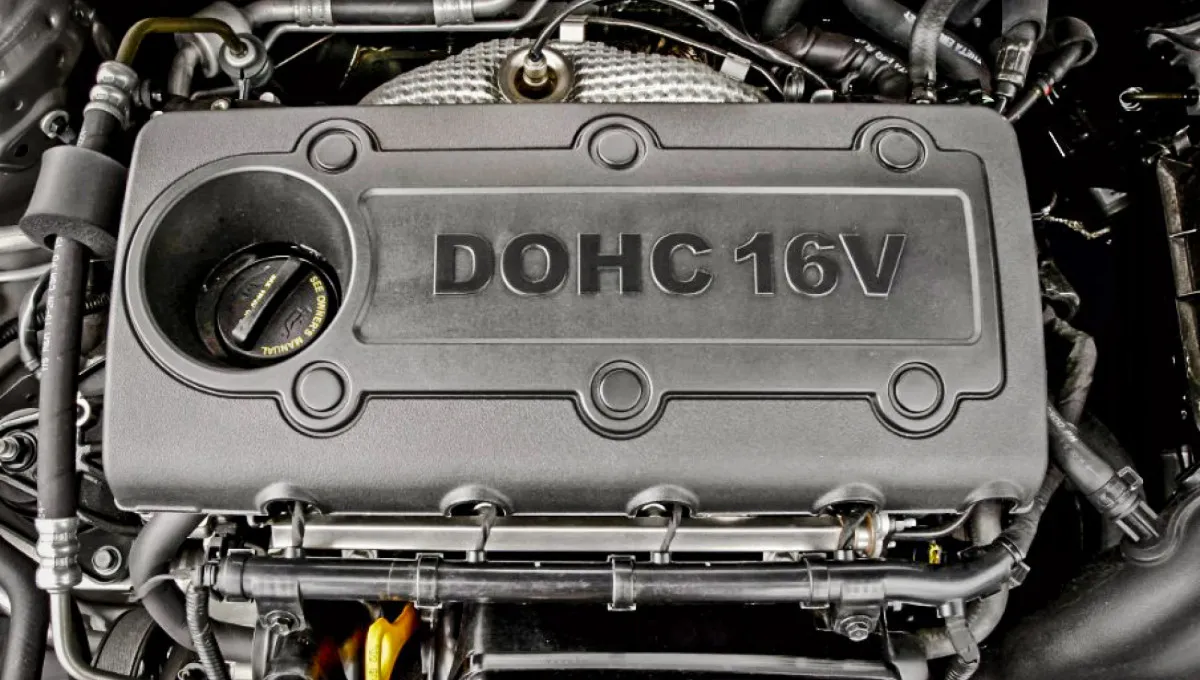

What “DOHC” on Your Engine Cover Really Means—and How It Differs From SOHC

Pop the hood on many modern cars and you’ll likely see large letters spelling out DOHC right on top of the engine.

The Ford Ranger That Wasn’t a Pickup: The Story of a Forgotten Edsel

Today, the Ford Ranger name is instantly recognizable—one of the market’s true long-timers.

What Does the “ASR OFF” Button Do — and Why Do Some Drivers Turn It Off?

Traction control is designed to keep you safe. So why do so many drivers choose to switch it off?

Why Drivers Should Check Their Engine Oil: What Makes It Turn Black — and When That’s a Red Flag

The color of your engine oil can reveal more about your vehicle’s health than you might think.

10 Supercars the Public Didn’t Understand: They Arrived at the Wrong Time

Which supercars were ahead of their time—and met with a lukewarm reception?