Nokian Tyres Unveils Experimental Tire Made with Birch Bark

A new study explores how birch bark–based raw materials change tire compounds—and what that could mean for drivers.

Nokian Tyres is pushing innovation in tire manufacturing by turning to an unexpected material: birch bark. Industry experts are already calling the approach unconventional, and the new technology has completed its first round of testing. Broader changes for the tire industry may follow.

The Finnish tire maker has taken a surprising step forward by introducing a concept tire called Betula, which for the first time incorporates a birch bark–derived component into its rubber compound. The breakthrough was made possible through a partnership with Swedish company Reselo, which specializes in renewable materials.

According to Nokian Tyres, the raw material used in the new tire comes from waste generated by the pulp, paper, and plywood industries. This not only reduces environmental impact but also puts previously unused byproducts to work. The two companies signed a collaboration agreement in 2024, and Betula represents the first tangible outcome of that partnership.

Betula is the first tire in Nokian Tyres’ history to feature birch bark in its tread compound. Engineers say the tread pattern is based on the design of the non-studded winter Hakkapeliitta R5, a model well known in cold-climate markets. The key difference lies in the materials: renewable and recycled content in the Betula tire reaches 93 percent—a record-setting figure for the industry.

Nokian Tyres emphasizes that birch bark is not only environmentally friendly but could also influence real-world tire performance. Exactly how the new material affects handling, grip, and durability has not yet been disclosed. The company notes that the potential for large-scale production using birch bark will need further evaluation.

The Betula concept tire has already undergone a series of tests at Nokian Tyres’ proving grounds in Ivalo and Nokia, Finland. Company representatives say the results are promising, though detailed data has not been released. Future steps will depend on a deeper analysis of the findings and expert feedback.

Interest in sustainable materials within the tire industry continues to grow each year, as manufacturers look to reduce reliance on petroleum-based inputs and lower their carbon footprint. In that context, Nokian Tyres’ experiment could serve as a benchmark for competitors—though a full-scale shift to such technologies is still some way off.

You may also be interested in the news:

Michelin Unveils AI-Powered Tires That Monitor Their Own Condition

Michelin introduces tires with AI technology that track their own wear and performance in real time.

Why Car Tires Lose Their Shape—and What That Means for Drivers and Safety

Tires don’t deform overnight, but when they do, the effects can show up in both vehicle behavior and overall road safety.

Germans Name the Best R18 All-Season Tires

Pirelli beats Continental and Michelin in AutoBild’s latest ranking of the best all-season tires

Why Buying Two Full Sets of Wheels Right Away Is a Bad Idea

Many car owners try to solve seasonal tire changes once and for all by buying two complete wheel sets—summer and winter—both mounted on alloy rims.

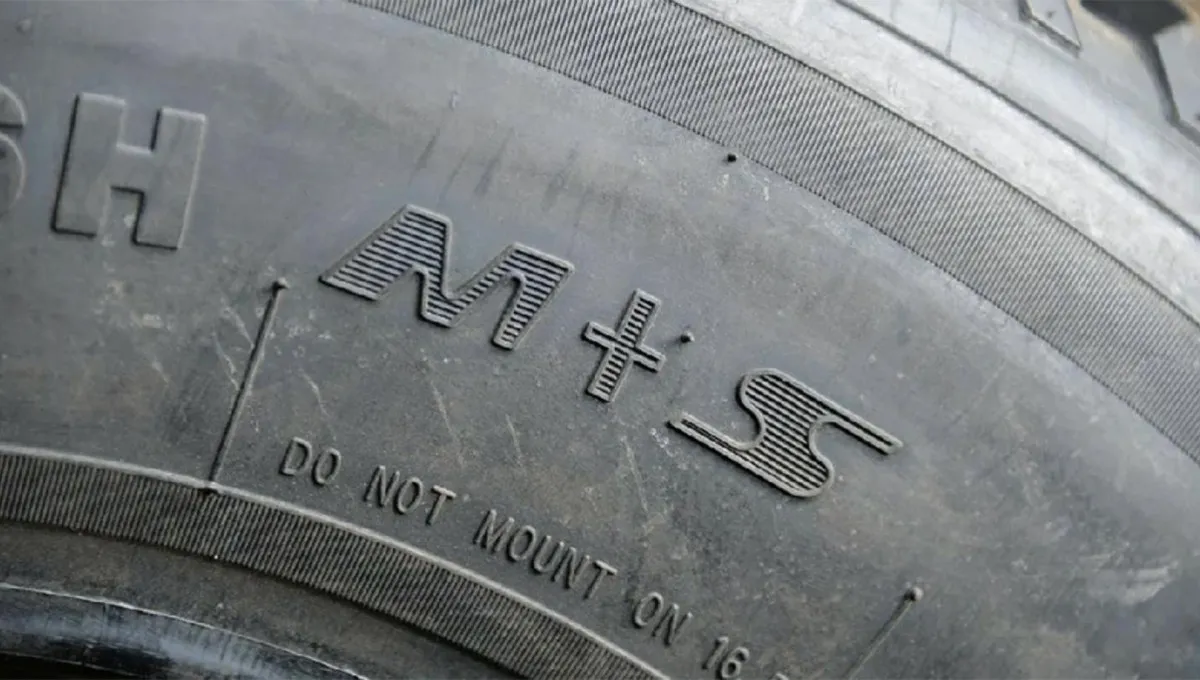

What M+S Means on Tires—and When It’s Actually OK to Drive on Them

Among the many symbols stamped on tire sidewalls, you’ve probably seen M+S. Here’s what it really stands for.